Boneham Manufacturing

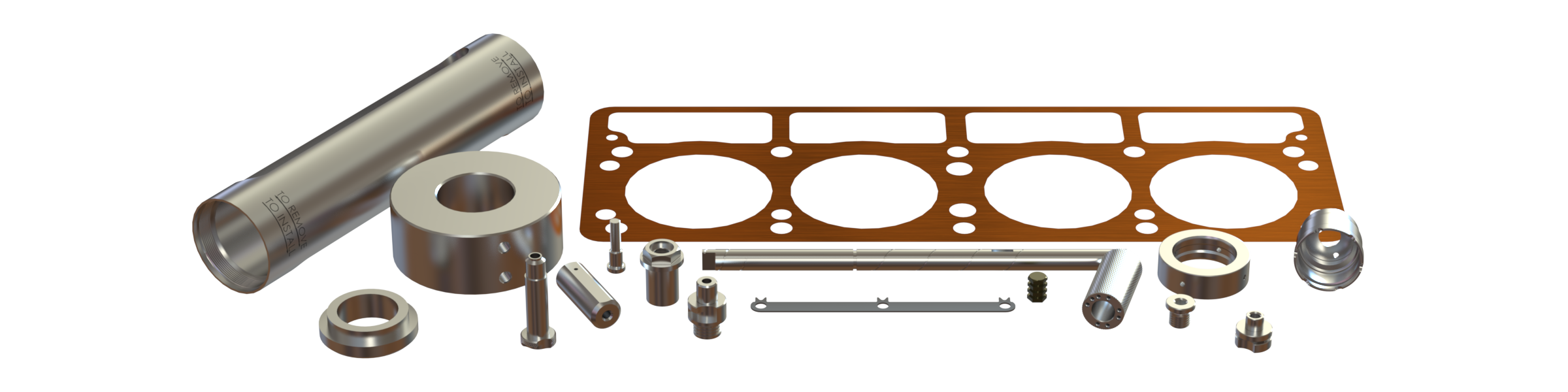

Boneham & Turner Ltd’s manufacturing plant has been the basis of its business since 1918; constantly investing in machinery and passing on a wealth of experience through apprenticeships and dedicated long serving staff of over 50 years service. Customers know that when a drawing is passed to Boneham & Turner, they can expect the very best in precision engineered solutions and workmanship. If its traceability or rapid production that are of the upmost importance, please let our sales staff know upon your enquiry with manufacturing solutions tailored to requirement. Boneham & Turner Ltd specialise in the manufacture of hardened and ground cylindrical components and welcome any drawing or variation on a standard.

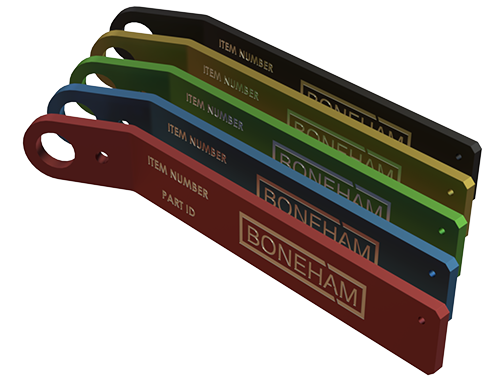

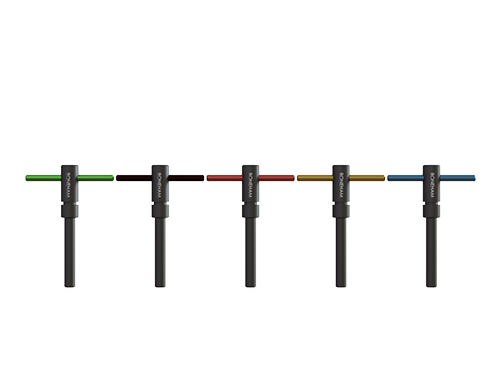

Our manufacturing facility is accredited to AS9100 Rev D with close adherence to processes outlined in our quality management system. As a UK manufacturer, we are always looking at innovating and moving the business forward to ensure our solutions support the changing demands of our customers here in the UK and around the World. Boneham specialises in manufacturing standard and special solutions. We manufacture, but not limited to, ISO, BS, ANSI, ASME, NAS and DIN standard jig bushes, dowel pins and location pins. All items can be manufactured to customer drawing and be customised for tool control or branding purposes. We also offer kitting for MRO and factory environments.

For more information and to speak with one of our sales team please go to the Contact us page.

Key Features

Areas of expertise

- Turning

- Milling

- Internal Grinding / Honing

- External Grinding

Specific Capabilities

- Bar feed from 1mm+ on multiple turning centre’s

- Coil feed from 0.8mm to 6mm

- Centreless grinding from 0.8mm

- Internal grinding from 1.27mm

- Cylindrical grinding

- Plunge grinding from 3mm

- CNC Milling with 4 axis capabilities

In-house Manufacturing Options

- FAST-TRACK Service

- Certification Options

- FAIRS

- PPAPs

- ISIR