ENHANCING ASSEMBLY EFFICIENCIES FOR MOTORSPORT

A leading advanced automotive technology firm sought a more efficient solution for the oil thermostat assembly in their latest advanced high-performance vehicle

A leading advanced automotive technology firm sought a more efficient solution for the oil thermostat assembly in their latest advanced high-performance vehicle

As part of National Apprenticeship Week, we welcomed 30 T-Level students from West Notts College to our business

On 13 February 2025 we welcomed Made in the Midlands and 40 of their members to a factory tour and networking event

It’s National Apprenticeship Week and our Apprentices are sharing their thoughts and experiences of working here at Boneham & Turner.Introducing … Noah Allsopp, 19 years old

It’s National Apprenticeship Week and our Apprentices are sharing their thoughts and experiences of working here at Boneham & Turner.Introducing … Naomi Richardson, 18 years old

It’s National Apprenticeship Week and our Apprentices are sharing their thoughts and experiences of working here at Boneham & Turner.Introducing … Jack Stafford, 22 years old

The University of Wolverhampton Racing (UWRacing) team have launched their new car, Revolution 500 EVO, at Autosport International

Happy New Year! To our customers, suppliers and friends, from all of us at The Boneham Group

After increased demand for Boneham solutions we have made a further investment with another Citizen L220-VIIILFV sliding head lathe with IEMCA bar feed, and Cromar swarf handling system

Apprenticeships are one of the most effective and enduring ways to prepare students for successful careers. Combining practical, on-the-job training with classroom learning, apprenticeships provide valuable real-world experience, helping individuals gain skills that are in demand by employers

We have a fantastic opportunity for an Apprentice Customer Service Administrator

Thank you to our customers, suppliers and friends who joined us at Advanced Engineering this year

Last week, we welcomed engineering students from All Saints Catholic Academy and the Indonesia International Student Mobility Awards (IISMA) University of Nottingham for our first student open day

Due to the continued investment and expansion within our Machine Shop, we are looking to recruit for a number of positions

We're exhibiting at Advanced Engineering 2024 on October 30 and 31 at the NEC Birmingham

We are pleased to announce that last week we were re-certified to EN9100:2018, after first achieving this accolade in 2018

.jpg)

Boneham and Turner are leading manufacturers of precision engineering solutions. We provide supply chains across a range of industries with fast and exact solutions, both from stock and tailored to specific requirements. Operating at the forefront of Motorsport, Aerospace, Defence, and Composite industries, our customers benefit from on-time deliveries, traceability, and reliability of our products. We work collaboratively with customers to develop solutions that add value to their manufacturing

Since the beginning of time, humans have been fascinated with flight

UK Government Forms Group of Aviation Experts to Make Zero-Emission Flight a Reality

Everything you need to know about SpaceX, including its goals, achievements and successes

Mechanical sealing plugs reduce operational cost and waste associated with threaded plugs, ball bearings and retaining adhesives. Zero defect solution with significant aftermarket ????quality gains for whole life value

The global aerospace parts manufacturing market is expected to reach $1.25 trillion by 2027, according to new research. Demand is being driven by an increase in freight traffic and passenger travel in developing countries, which is resulting in a greater demand for advanced aircraft

.jpg)

Cutting edge technology can make all the difference in the world of motorsports. Innovative design and manufacturing can make all the difference between winning and losing, which is why race teams are constantly looking to improve performance

.jpg)

National Apprenticeship Week 2019 sees Nottinghamshire based precision component manufacturer Boneham and Turner Ltd create three new exciting apprenticeship opportunities to encourage young minds into engineering

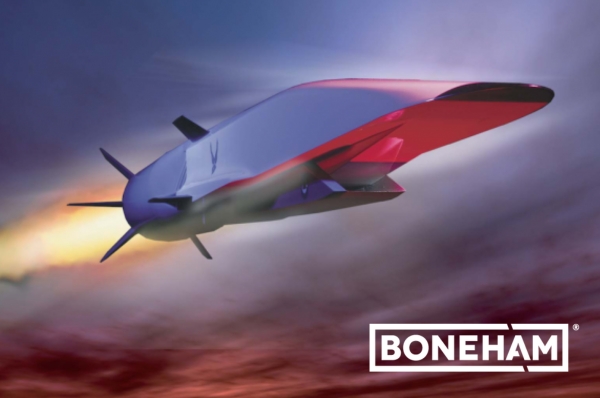

Researchers at the University of Central Florida (UCF) are working on technologies that could lead to hypersonic flight

.jpg)

National Aviation Day is an American national holiday held on August 19th that celebrates the world-changing achievements of Orville and Wilbur Wright

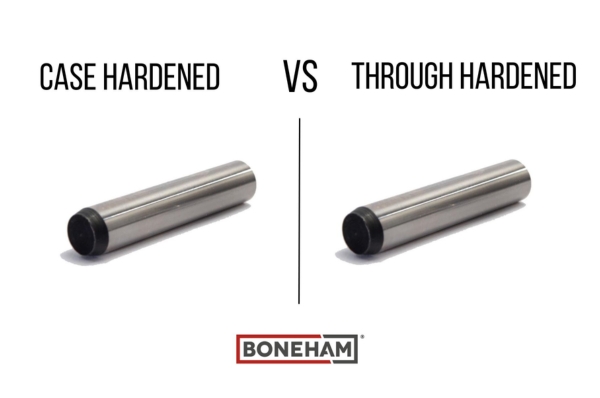

The properties of the tooling components you use matter. Depending on your application, you might need wear resistant drill bushes or a high strength composite location component, with fracture resistance. Hardening is the process manipulating the properties of your component using temperature. Knowing the difference between through hardening and case hardening is an important part of choosing the right component for your application. This article explores the 2 different types of hardening used

.jpg)

Drilling accurate holes is one of the most important parts of manufacturing and engineering. An accurate hole with an exact diameter helps speed up work piece alignment and ensures the final product is high quality. To achieve the ultimate hole, just follow this (relatively) simple three step process. But before getting stuck into the three steps, you should take to drill the perfect hole, you should ensure you follow these standard procedures

The motorsport industry is never satisfied. There’s always a milli-second to be shaved in qualifying; the cars are never perfect, and Pit-Stops can never be too quick (although McLaren got close). The constant desire for improvement means that 25-30% of revenue in the British motorsport industry is spent on R&D